Generate value through preventive maintenance effectiveness analysis and improvement

You are required to make asset management decisions to balance your cost, risk and the performance of your assets to deliver on your business expectations, goals and targets.

- To make decisions with the best possible outcome you need accurate information about your physical assets.

- You need to understand your preventive maintenance effectiveness and where you need to review and reset the preventive maintenance approach to provide the best value for your organisation.

We analyse the data you already have to generate actionable information to enable better decision making and create value for your organisation.

- We will enable you to make informed decisions on preventive maintenance improvement through our preventive maintenance effectiveness analysis.

- Currently you may not be using the data you collect to its fullest potential to deliver preventive maintenance effectiveness improvement.

- We will unlock the information you hold to provide essential insight about your preventive maintenance effectiveness and enable you to drive improvement and generate value.

Unlock the power of informed decision making based on your asset data

Our advanced data analytics platform and expert engineering capability will provide maximum insight about the effectiveness of your preventive maintenance from your data, no matter the information system or how poor or limited that data appears to be at first sight. With our approach using a combination of machine learning, expert engineers and heuristic and meta-heuristic analysis, low-quality data is utilised to provide insightful and powerful reports designed to optimise the specific decisions which need to be taken by a range of stakeholders.

So how does it work and what do you get?

Extract data from your information systems

We will work with your teams to extract the required data fields from your information systems. To assist in this process, we will provide you with data extract requirement and templates. The data that we will require is both master data and transactional data.

The minimum data required for the analysis is:

- Location / asset / equipment registers master data; and

- Work order data.

We also process other data sources for enhanced outcomes. These are but not limited to:

- Work requests or notifications;

- Operator logs;

- Downtime logs;

- Asset utilisation systems; and

- Condition monitoring data

Data transfer

We utilise ShareFile by Citrix, a secure encrypted data transfer service for data transfer and secure storage at rest. This enables your team to securely transmit the data to us without limits to file sizes.

Preventive maintenance effectiveness data analysis

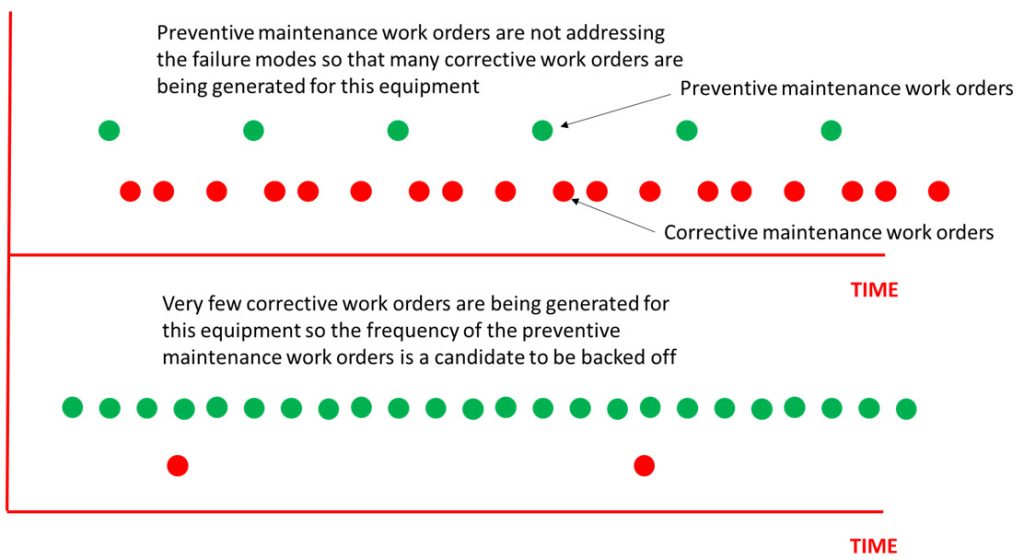

We will undertake analysis based on data from your asset information systems and provide you PM effectiveness reporting which will allow you to make informed decisions in the optimisation of your preventive maintenance. This analysis will focus on the two key concerns with the specification of preventive maintenance (PM) in an enterprise:

- Where preventive maintenance strategy is not effectively managing down risk of failures.

- PM’s are undertaken although there is still a high quantity of corrective work orders for the equipment, meaning ether PM’s are ineffective in addressing the failure modes or are not being undertaken effectively by the teams. Adjustment here can manage down the rate of downtime of the equipment.

- Where the PM’s are excessive and there are savings to be made.

- PM’s are being undertaken although very few corrective work orders are being generated. This means the frequency of the PM can be reviewed and relaxed which will provide resource and cost savings.

The analysis considers these two questions by searching all the work order history and for each asset considers the following scenarios:

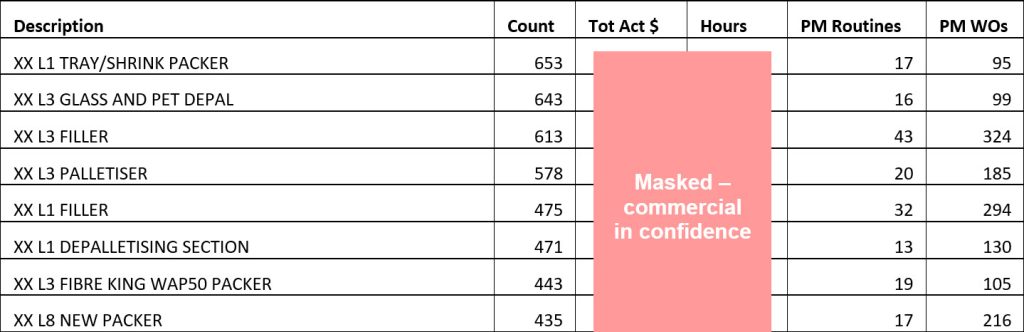

Covaris reports provide detailed information of where the client needs to look to commence improving their preventive maintenance strategy.

In this example extract below a number of machines have high rates of corrective work and the current PM strategy is obviously not effective in addressing the failure modes in these machines.

Reporting

We will provide a comprehensive report which will allow you to work with your teams to investigate specific preventive maintenance performance issues identified. You can make informed decisions on preventive maintenance optimisation using empirical evidence from this analysis. The time frame from receipt of data to the issue of the report is between 2 to 3 weeks. We can provide this type of in depth preventive maintenance performance reporting very quickly due to our proprietary software which we have developed over 18 years, our experienced engineers and analytical processes.